INSTALLATION OF THE UNDERCOUNTER

WATER PURIFIER FILTER HOUSING

1. For small one to three stage systems, select a suitable location for the filter housing(s) under the kitchen sink or on the under sink doors. The doors can be an advantage for persons who have trouble bending or reaching. Remember this unit must be serviced at regular intervals. Therefore the system should be reasonably accessible to enable the sump to be unscrewed to change or clean the cartridge(s). A clearance of 10 inches is desirable for ease of removal.

2. Fit the head of the filter housing to the bracket using the 3 self-tapping screws provided (Fig A.). Ensure the bracket corresponds to the arrow on the head, indicating the direction of water flow.

3. Secure the bracket to the wall or door with the two screws provided. For multi-stage units the short hose inter-connecting the head assemblies should be installed before the heads are mounted to the wall. It is not nessessary to mount the filter. You can stand it upright into any area under the sink.

SADDLE VALVE

4. SHUT OFF THE WATER SUPPLY TO THE SINK. Select a suitable position for the location of the line piercing saddle valve on the copper (or plastic) COLD water line leading to the main faucet. Ensure that the saddle valve is located ABOVE the sink shut-off valve (if you have one). It must also be accessible enough to allow for isolation of the filter during cleaning or replacement of the cartridge(s).

5. Back off the tap FULLY to retract the piercing tip into the washer.

6. Back off the securing bolt and remove the pipe backing sleeve. Match the curvature of the sleeve to the size of your main water line.

7. Slide the valve around the line and tighten the securing bolt until it butts up firmly against the sleeve. Do not tighten to the point of crushing the line.

8. Turn the tap in until you feel the piercing tip contact the water line. Turn the tap in and out in increasing amounts until you feel the tap turn freely inward. It has then penetrated the line fully. Continue turning in until it bottoms out. Leave the tap turned fully in. This is the "off" position.

FAUCET

9. Select a suitable position for the faucet as close to the sink edge as practical, but ensuring access from the underside to enable installation of the mounting hardware and hose.

10. Mark and drill the faucet hole (1/2 inch.) with a suitable bit for the surface being penetrated.

11. Assemble the faucet as shown in Fig C.

HOSE CONNECTIONS

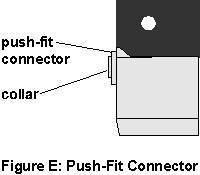

Note: Starting in late 2000, John Guest "Push Fit" hose/tube connections were supplied with the faucet, saddle valve and ball valve shut-off for ease of installation. John Guest fittings do not require the Figure D. hardware. If your filter has John Guest fittings, disregard the references to figure D hardware and procedures.

12. Cut the hose to the desired length between the saddle valve and the head. Leave enough slack to be able to secure the hose out of the way.

13. Install the nut, insert and sleeve as shown in Fig D and secure to the saddle valve

Note: The hose may be easily removed from a John Guest fitting by pushing the collar on the push-fit connector all the way in and holding it there while gently pulling back on the hose. Excessive force is not required.

14. Repeat these procedures for the hose between the faucet and the head.

15. Inspect the cartridge(s) for obvious damage prior to installation.

An optional " John Guest Push-Fit " connector Ball Valve can be purchased.

Go here for Countertop Filter installation instructions

<< Back to Water Purifiers |